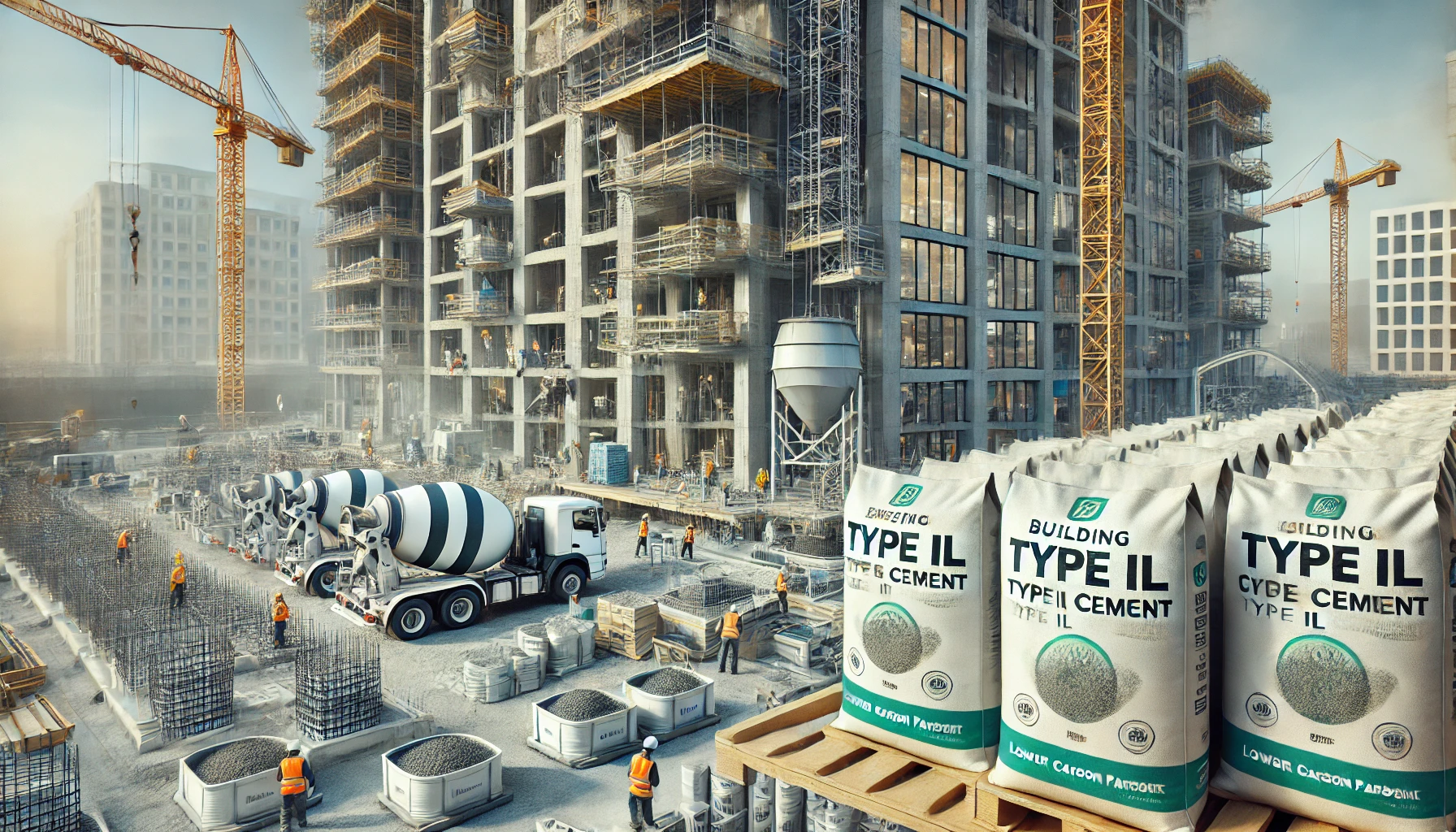

Type IL cement, also known as Portland-Limestone Cement (PLC), has a lower carbon footprint compared to traditional Portland cement (Type I) due to several factors. The primary advantage of Type IL cement is its increased limestone content, which means that less clinker, the most carbon-intensive component of cement, is needed in its production. Studies have shown that incorporating more limestone into the cement mix reduces CO2 emissions because the clinker production process involves the calcination of limestone, which releases significant amounts of CO2. For instance, a study in South Africa comparing different types of Portland cement found that Type IL cement (CEM II/B-L) reduced global warming impacts by approximately 14% compared to traditional Portland cement (CEM I) (Ige & Olanrewaju, 2023). Another study demonstrated that Type IL cement can achieve CO2 emission reductions of 20-30% compared to traditional Portland cement by reducing the need for high-temperature processing and associated energy consumption (Barcelo et al., 2014). These reductions in emissions, along with comparable performance in terms of strength and durability, make Type IL cement a more environmentally friendly alternative.

| Serial Number | Paper Title | Insight | Citation Count |

|---|---|---|---|

| 1 | Cement and carbon emissions (Barcelo et al., 2014) | This paper discusses the carbon footprint of cement production and highlights how new clinkers requiring less limestone can reduce CO2 emissions by 20-30% compared to traditional Portland cement. | 375 |

| 2 | Comparative Life Cycle Assessment of Different Portland Cement Types in South Africa (Ige & Olanrewaju, 2023) | This study shows that Type IL cement can reduce global warming impacts by 14% compared to traditional Portland cement, due to lower clinker content and increased limestone utilization. | – |

| 3 | Comparative life cycle assessment (LCA) of geopolymer cement manufacturing with Portland cement in Indian context (Meshram & Kumar, 2021) | This paper compares the environmental impacts of geopolymer cement and traditional Portland cement, showing that the former can reduce CO2 emissions significantly, highlighting the benefits of alternative binders. | 8 |

| 4 | Reducing the carbon footprint of lightweight aggregate concrete (Kanavaris et al., 2020) | This study explores methods to reduce the carbon footprint of lightweight aggregate concrete by using alternative materials like ground granulated blast-furnace slag, achieving a reduction in Portland cement content by approximately 40%. | 1 |

| 5 | Louisiana’s Laboratory Experience with Type IL Portland Cement (Rupnow & Icenogle, 2015) | This research details the benefits of Type IL cement in Louisiana, including its comparable strength properties to Type I cement and reduced shrinkage, supporting its use in various construction applications. | – |